7705

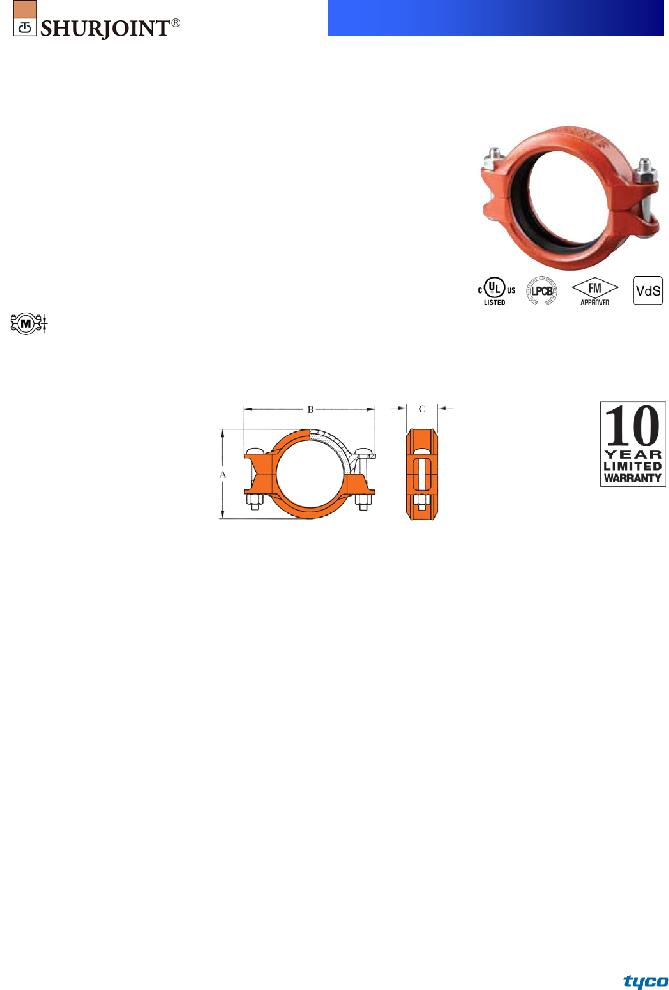

MODEL 7705 STANDARD FLEXIBLE COUPLING

The Model 7705 Standard Flexible Coupling is a standard flexible coupling for use in a variety of general piping applications of moderate pressure services. The model 7705 couplings features flexibility that can deal with misalignment, distortion, thermal stress, vibration and noise and also resist seismic tremors. With the use of Model 7705 couplings you can even design a curved layout. See Typical Applications – Flexible Couplings on Shurjoint cut sheet

All Model 7705 couplings are comprised of two identical ductile iron housings segments, EPDM rubber gasket and plated track bolts & nuts. Housings segments are supplied with our standard painted finishes, i.e. orange or RAL3000 red. Optional finishes such as hot dipped zinc galvanized and custom epoxy coatings are available.

7705 couplings should always be installed so that the coupling bolt pads make metal to metal contact.

For Fire Protection pressure rating, listing, and approval information, refer to Data Sheet

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Full warranty terms |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

can be |

found on |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

www.shurjoint.com |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

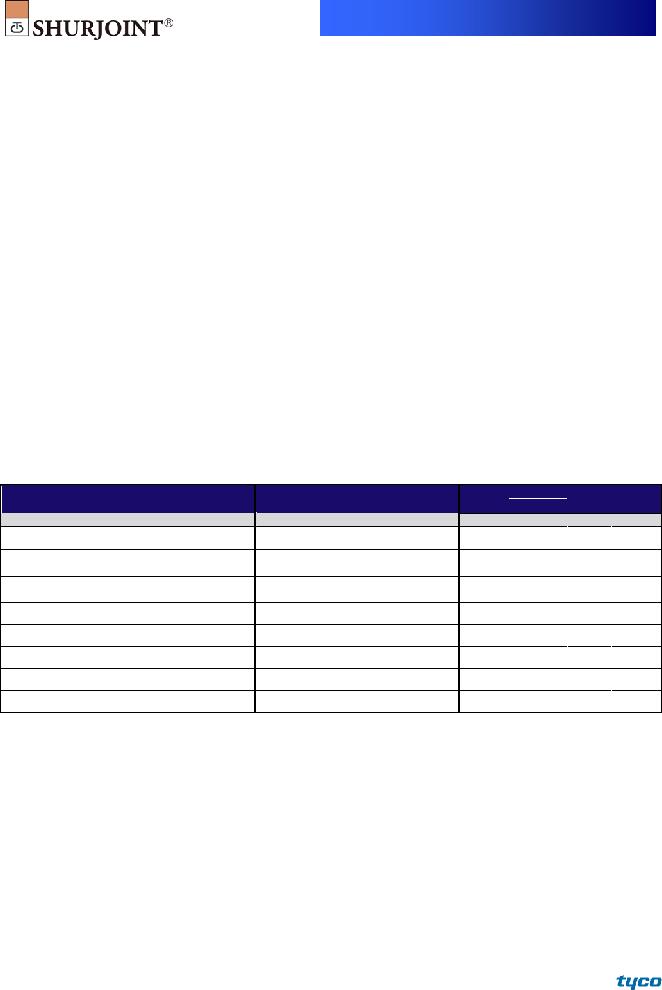

Model 7705 Standard Flexible Coupling |

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

Max. |

|

ASME/ANSI |

|

Max. |

|

|

|

|

Angular Movement **† |

|

|

Dimensions |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

Working |

|

Pressure Class |

|

End |

|

Axial |

|

|

|

|

|

|

|

|

|

|

|||||||

|

Nominal |

|

|

Pipe |

|

Pressure |

|

Rating^ |

|

Load |

|

Displace- |

|

Deg. Per |

|

Per |

|

|

|

|

|

|

|

|

Bolt |

|

|

|

|

|

Size |

|

|

O.D. |

|

(CWP)* |

|

@100oF/@38oC |

|

(CWP) |

|

ment † |

|

Coupling |

|

Pipe |

|

A |

|

B |

C |

|

Size |

|

Weight |

|

|||

|

in |

|

|

in |

|

PSI |

|

PSI |

|

Lbs |

|

in |

|

|

(o) |

|

in/ft |

|

in |

|

in |

|

in |

|

|

in |

|

Lbs |

|

|

mm |

|

|

mm |

|

Bar |

|

Nom. Class |

|

kN |

|

mm |

|

|

|

|

mm/m |

|

mm |

|

mm |

|

mm |

|

|

mm |

|

Kgs |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

1 |

|

1.315 |

500 |

300 |

670 |

0.0625 |

|

|

2o- 45’ |

0.58 |

2.24 |

3.94 |

|

1.81 |

|

|

⅜ x 1¾ |

1.3 |

|

||||||||||

25 |

33.7 |

35 |

150 |

3.12 |

1.6 |

|

|

48 |

57 |

100 |

|

46 |

|

|

M10 x 45 |

0.6 |

|

||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||||||

1¼ |

1.660 |

500 |

300 |

1080 |

0.0625 |

|

|

2o - 10’ |

0.46 |

2.60 |

4.06 |

|

1.81 |

|

|

⅜ x 2⅛ |

1.5 |

|

|||||||||||

32 |

42.4 |

35 |

150 |

4.94 |

1.6 |

|

|

38 |

66 |

103 |

|

46 |

|

|

M10 x 55 |

0.7 |

|

||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||||||

1½ |

1.900 |

500 |

300 |

1410 |

0.0625 |

|

|

1o - 54’ |

0.4 |

2.83 |

4.25 |

|

1.81 |

|

|

⅜ x 2⅛ |

1.6 |

|

|||||||||||

40 |

48.3 |

35 |

150 |

6.41 |

1.6 |

|

|

33 |

72 |

108 |

|

46 |

|

|

M10 x 55 |

0.7 |

|

||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||||||

2 |

2.375 |

500 |

300 |

2210 |

0.0625 |

|

|

1o - 31’ |

0.32 |

3.31 |

5.08 |

|

1.89 |

|

|

⅜ x 2⅛ |

1.8 |

|

|||||||||||

50 |

60.3 |

35 |

150 |

9.99 |

1.6 |

|

|

27 |

84 |

129 |

|

48 |

|

|

M10 x 55 |

0.8 |

|

||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||||||

2½ |

2.875 |

500 |

300 |

3240 |

0.0625 |

|

|

1o - 15’ |

0.26 |

3.90 |

5.59 |

|

1.89 |

|

|

⅜ x 2⅛ |

2.0 |

|

|||||||||||

65 |

73.0 |

35 |

150 |

14.64 |

1.6 |

|

|

22 |

99 |

142 |

|

48 |

|

|

M10 x 55 |

0.9 |

|

||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

76.1 mm |

3.000 |

500 |

300 |

3530 |

0.0625 |

|

|

1o - 12’ |

0.25 |

4.02 |

5.79 |

|

1.89 |

|

|

⅜ x 2⅛ |

2.1 |

|

||||||||||

|

76.1 |

35 |

150 |

15.91 |

1.6 |

|

|

21 |

102 |

147 |

|

48 |

|

|

M10 x 55 |

1.0 |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

3 |

3.500 |

500 |

300 |

4800 |

0.0625 |

|

|

1o - 02’ |

0.22 |

4.57 |

6.65 |

|

1.89 |

|

|

½ x 3 |

2.8 |

|

|||||||||||

80 |

88.9 |

35 |

150 |

21.71 |

1.6 |

|

|

18 |

116 |

169 |

|

48 |

|

|

M12 x 75 |

1.3 |

|

||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

101.6 mm |

4.000 |

500 |

300 |

6280 |

0.0625 |

|

|

0o - 54’ |

0.19 |

5.07 |

7.90 |

|

2.05 |

|

|

½ x 3 |

3.6 |

|

||||||||||

|

101.6 |

35 |

150 |

28.36 |

1.6 |

|

|

16 |

129 |

200 |

|

52 |

|

|

M12 x 75 |

1.6 |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

108.0 mm |

4.250 |

500 |

300 |

7080 |

0.1250 |

|

|

1o - 42’ |

0.36 |

5.43 |

7.56 |

|

2.05 |

|

|

½ x 3 |

4.1 |

|

||||||||||

|

108.0 |

35 |

150 |

32.05 |

3.2 |

|

|

30 |

138 |

192 |

|

52 |

|

|

M12 x 75 |

1.9 |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

4 |

4.500 |

500 |

300 |

7940 |

0.1250 |

|

|

1o - 36’ |

0.34 |

5.71 |

7.76 |

|

2.05 |

|

|

½ x 3 |

4.1 |

|

|||||||||||

100 |

114.3 |

35 |

150 |

35.89 |

3.2 |

|

|

28 |

145 |

197 |

|

52 |

|

|

M12 x 75 |

1.9 |

|

||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

133.0 mm |

5.250 |

450 |

300 |

9730 |

0.1250 |

|

|

1o - 23’ |

0.29 |

6.50 |

9.09 |

|

2.05 |

|

|

⅝ x 3½ |

5.1 |

|

||||||||||

|

133.0 |

31 |

150 |

43.05 |

3.2 |

|

|

24 |

165 |

231 |

|

52 |

|

|

M16 x 90 |

2.3 |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

139.7 mm |

5.500 |

450 |

300 |

10680 |

0.1250 |

|

|

1o - 18’ |

0.28 |

6.69 |

9.17 |

|

2.05 |

|

|

⅝ x 3½ |

5.9 |

|

||||||||||

|

139.7 |

31 |

150 |

47.49 |

3.2 |

|

|

23 |

170 |

233 |

|

52 |

|

|

M16 x 90 |

2.7 |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

5 |

5.563 |

450 |

300 |

10930 |

0.1250 |

|

|

1o - 18’ |

0.27 |

6.77 |

9.21 |

|

2.05 |

|

|

⅝ x3½ |

5.9 |

|

|||||||||||

125 |

141.3 |

31 |

150 |

48.59 |

3.2 |

|

|

23 |

172 |

234 |

|

52 |

|

|

M16 x 90 |

2.7 |

|

||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

Rev.G 20130704 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||